|

ZL型双锥篮离心机

收藏

ZL型离心机是进料、过滤、分离及排料均在全速运转下自动连续进行的离心机,本机与物料接触部位均采用不锈钢材料耐腐蚀,且处理量大、工作效率高,劳动强度低。 广泛适用于化工、医药、食品等行业,特别适用于果汁、酒槽、实验的分离。 ZL centrifuge is a kind of centrifuge which automatically and continuously carries out feeding, filtering, separating and discharging at full speed. stainless steel is used in the contact part between this machine and material, and the treatment capacity is large, the working efficiency is high, and the labor intensity is low. Widely used in chemical, pharmaceutical, food and other industries, especially suitable for fruit juice, wine trough, experimental separation.

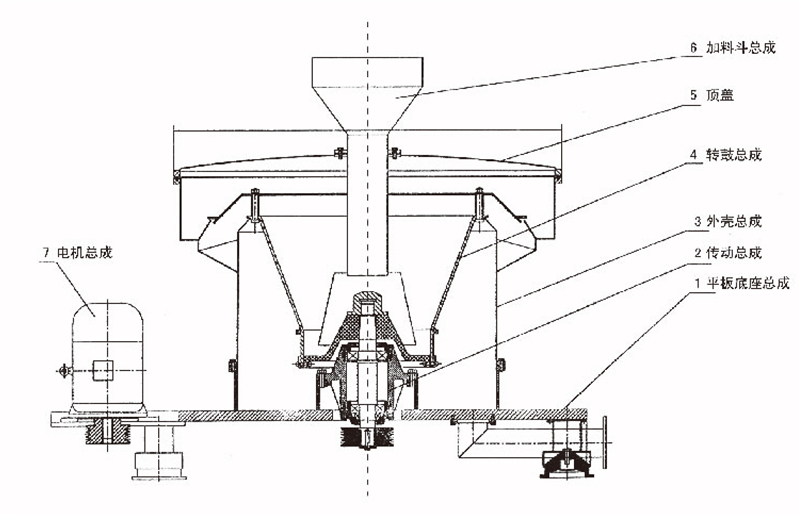

本离心机主要由传鼓、传动座、机座、内壳、外机壳和上盖组成。锥型转鼓内表面有筛网,中间装用布料器。物料从安装在与转鼓同轴中心同一轴线的进料管垂直进入配器,在离心机的作用下,实现固液分离,固相物料在网面上移至大端而完成脱液,并借助于惯性实现卸料,通过内机壳与外机壳的环形通道下落进行收集。 The centrifuge is mainly composed of a drum, a transmission seat, a machine base, an inner shell, an outer shell and an upper cover. There is a screen on the inner surface of the conical drum, and a distributor is installed in the middle. The material enters the apparatus vertically from the feed pipe mounted on the same axis as the coaxial center of the drum, under the action of a centrifuge, the solid-liquid separation is realized, the solid material is moved to a large end on the mesh surface to complete the stripping, and the discharge is realized by means of inertia, The collection is carried out through the fall of the annular channel between the inner casing and the outer casing.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||