|

PSD吊袋上部卸料离心机

收藏

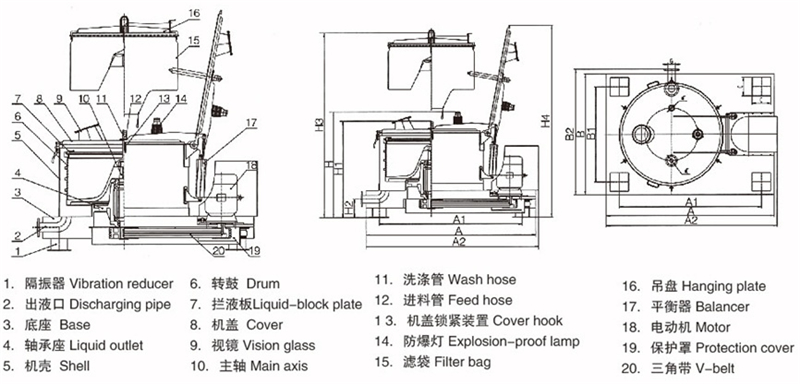

1.采用变频控制,启动平稳,分离因数可调。 2.吊袋卸料,晶粒不易破碎;劳动强度低,工效高;通用性强,适用范围广。 3.结构设计合理,结构件圆滑过渡,表面抛光处理,无卫生死角。翻盖式外壳,可对外壳与转鼓夹层空间进行彻底清洗。 4.机座与机壳为整体焊接结构,承载强度高。 5.平板式机座,机器重心低,占地空间小,平板机座可作为操作平台,操作方便。 6.四点支撑液态阻尼减振器,减振效果好,简化日常保养。 7.外壳翻盖设置进料管、洗涤管、观察镜、照明孔等常规管口。 8.配置在线清洗系统(选装),可对离心机外壳内壁、转鼓内外表面、集液槽表面等内部不可见部位进行清洗,保证了洁净度要求,符合GMP规范。 9.密闭结构,密封件采用硅橡胶或氟橡胶,配置氮气保护系统(选装),可实现密闭防爆要求,适合于有毒和易燃易爆场合的应用。 10.配置液压式悬臂吊(选装),卸料方便,符合卫生要求。 1. Adopt frequency conversion control, start smoothly, separation factor can be adjusted. 2. The hanging bag unloading, the grain is not easy to break; the labor intensity is low, the work efficiency is high; the versatility is strong, the scope of application is wide. 3. Reasonable structure design, smooth transition of structural parts, surface polishing treatment, no sanitary dead angle. Flip shell, can thoroughly clean the shell and drum sandwich space. 4. The base and shell are welded as a whole, and the bearing strength is high. 5. Flat machine base, low center of gravity of the machine, small space occupied, flat machine seat can be used as an operating platform, easy to operate. 6. Four-point support liquid damping shock absorber, good damping effect, simplify daily maintenance. 7. The shell flip is provided with a conventional pipe mouth such as a feed pipe, a washing pipe, an observation mirror, an illumination hole, etc. 8. Equipped with on-line cleaning system (optional), the inner wall of centrifuge shell, the inner and outer surface of drum, the surface of liquid collecting tank and other internal invisible parts can be cleaned, which ensures the cleanliness requirements and conforms to GMP specification. 9. Sealed structure, sealed with silicone rubber or fluorine rubber, equipped with nitrogen protection system (optional), can achieve closed explosion-proof requirements, suitable for toxic and flammable and explosive applications. 10. Equipped with hydraulic cantilever crane (optional), easy to discharge, in line with health requirements.

待分离的物料经进料管进入高速旋转的离心机转鼓内,在离心力场的作用下,物料通过滤布(滤网)过滤,液相经出液管排出,固相则截留在转鼓内。待转鼓内滤饼达到机器规定的装料量时,停止进料,对滤饼进行洗涤,同时将洗涤液滤出。 滤饼脱液达到要求后,停机。专用的吊具将滤袋连同滤饼一起吊出至指定卸料处,打开卸料口,将滤饼卸出,然后将滤袋复位,进入待机状态。 The material to be separated enters the high-speed rotating centrifuge drum through the feed tube. under the action of the centrifugal force field, the material is filtered through the filter cloth (filter net), the liquid phase is discharged through the outlet tube, and the solid phase is intercepted in the drum. When the filter cake in the rotating drum reaches the loading quantity specified by the machine, the feed is stopped, the filter cake is washed, and the washing liquid is filtered out at the same time. After the filter cake is removed from the liquid to meet the requirements, stop. The special hoist will lift the filter bag together with the filter cake to the designated discharge place, open the discharge port, unload the filter cake, and then reset the filter bag and enter the standby state.

用于固相为颗粒状的悬浮液的固液相分离,也可用于纤维状物料的固液相分离。 如:石膏、硫酸铜、氯化钾、硼砂、染料、农药药剂,食盐、味精、食品添加剂、淀粉、制糖、化学调味料,抗生素、维生素,铜、锌、铝等矿产物、金属精制,污泥处理、污水处理等。 It can be used for solid-liquid phase separation of solid-liquid suspension with granular solid phase, and can also be used for solid-liquid phase separation of fibrous materials. Such as gypsum, copper sulfate, potassium chloride, borax, dyes, pesticide agents, salt, monosodium glutamate, food additives, starch, sugar, chemical condiments, antibiotics, vitamins, copper, zinc, aluminum and other mineral products, metal refining, Sludge treatment, sewage treatment, etc.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||