|

LW卧式螺旋卸料沉降式离心机(三相分离型)

收藏

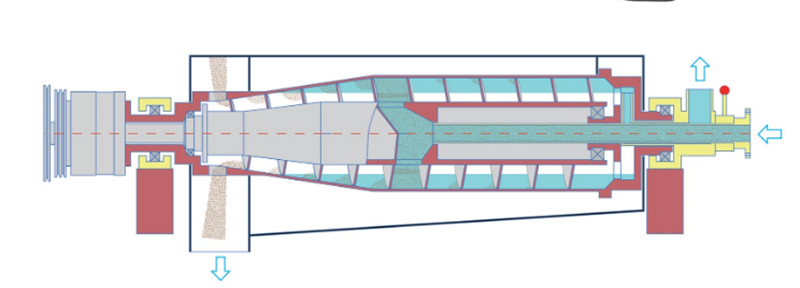

LW型离心机是一种卧式螺旋卸料,连续操作的沉降设备。转鼓与螺旋以一定差速同向高速旋转,物料由进料管连续引入输料螺旋内筒,加速后进入转鼓,在离心力场作用下,较重的固相物沉积在转鼓壁上形成沉渣层。 输料螺旋将沉积的固相物连续不断定推至转鼓锥端,经排渣口排出机外,较轻的液相物则形成内层液环,由转鼓大端溢流口连续溢出转鼓,经排液口排出机外。 本机能在全速运转下,连续进料、分离、洗涤和卸料。具有结构紧凑、连续操作、运转平衡、适应性强、生产能力大、维修方便等特点。 适合分离含固相物粒度大于0.005mm、浓度范围在2-40%的悬浮液。广泛用于化工、轻工、制药、食品、环保等行业。 LW centrifuge is a kind of horizontal spiral discharge, continuous operation of sedimentation equipment. The drum and the screw rotate at the same speed at a certain difference. the material is continuously introduced into the inner cylinder of the feeding screw from the feed tube and accelerated into the drum. Under the action of centrifugal force field, the heavier solid deposits on the drum wall to form a sediment layer. The solid phase deposited by the feeding screw is continuously pushed to the cone end of the drum, and the lighter liquid phase is discharged from the machine through the slag discharge orifice, and the lighter liquid phase is formed into an inner liquid ring, which is continuously overflowed from the drum through the overflow port at the large end of the drum and discharged out of the machine through the discharge port. The machine is operated at full speed, continuous feeding, separation, washing and unloading. The utility model has the characteristics of compact structure, continuous operation, operation balance, strong adaptability, large production capacity, convenient maintenance and so on. It is suitable for the separation of suspension containing solid phase with particle size larger than 0.005mm and concentration range of 2 ≤ 40%. Widely used in chemical, light industry, pharmaceutical, food, environmental protection and other industries.

该机型主要用于固-液-液分离,即对一种固相(密度最大)和两种密度不同的液相进行分离。转鼓和螺旋以差速同向高速旋转,物料经进料管进入。 在离心力作用下,固相物料沉积在转鼓壁上形成沉渣层,两种液相物料分别形成轻液相环和重液相环,由转鼓壁开始向内依次形成固相层、重液相层和轻液相层。螺旋将沉积在转鼓壁上的固相物料连续不断的推至转鼓锥端,经排渣口排出机外。 轻液相由转鼓大端的溢流口连续溢出,重液相经转鼓大端向心泵排出。从而实现三相分离。 The machine is mainly used for solid-liquid separation, that is, the separation of one solid phase (maximum density) and two kinds of liquid phase with different density. The drum and screw rotate at the same speed and at the same speed, and the material enters through the feed pipe. Under the action of centrifugal force, the solid phase material is deposited on the drum wall to form a sediment layer. the two kinds of liquid phase materials form a light liquid phase loop and a heavy liquid phase loop respectively, and form a solid phase layer, a heavy liquid phase layer and a light liquid phase layer in turn from the drum wall. The solid material deposited on the drum wall is continuously pushed to the cone end of the drum and discharged out of the machine through the slag discharge port. The light liquid phase is continuously overflowed by the overflow port at the large end of the drum, and the heavy liquid phase is discharged from the central pump through the large end of the drum. So as to achieve three-phase separation.

|